3D Scanning and Printing

This week there are also two types of assignments, one group and one individual.

Group assignment:

Test the design rules for your 3D printer(s)

Individual assignment:

Design and 3D print an object (small, few cm3, limited by printer time) that could not be made subtractively.

3D scan an object (and optionally print it)

Learning Outcomes

To understand the working of 3D Printers.

To know about different filament material used for 3d printing.

To understand the design rules of the 3D Printer.

To understand the print settings.

To understand 3D Scanning.

Additive Manufacturing & Types of 3D Printers:-

Since I am a mechanical engineer by education, I already had knowledge about various types of 3D printers and various technologies used.

But, I like to explain it once again for the newbies that visited my page. The term “3D printing” is increasingly used as a synonym for

additive manufacturing. However, “additive manufacturing” better reflects the professional manufacturing process that differs significantly

from conventional, subtractive manufacturing methods. For example, instead of milling a workpiece from a solid block, additive manufacturing

builds the part up layer by layer from material supplied as a fine powder. Various metals, plastics and composite materials can be used.

Additive manufacturing is relevant in many areas and for numerous industries. Whether used for building visual and functional prototypes or

small and medium series - and increasingly for series production. This method offers convincing advantages conventional methods cannot achieve.

Product development and market entry can be significantly accelerated, agile product customization and functional integration can be achieved

more quickly and at a lower cost. In this way, additive manufacturing gives large OEM manufacturers from a wide variety of industries the opportunity

to differentiate themselves on the market in terms of customer benefits, cost reduction potential and sustainability targets. There are various types

of additive manufacturing technologies:

In my fablab sindoh 3dwox DP200

1.Technology: Fused filament fabrication (FFF)

2.Type: Material extrusion

3.Year: 2017

4.Manufacturer: Sindoh

5.Manufacturer country: South Korea

Materials:

1.Filameter diameter: : 1.75 mm

2.Printable materials : ABS, PLA, PVA,PETG

Build volume:

1.3D print size : Medium

2.Print size millimeters (xyz) : 228 x 200 x 300 mm

3.Print size inches (xyz): 8.9 x 7.9 x 11.8 inches

3D printer and printing properties

1.Layer height : 20 – 200 Microns

2.Nozzle size: : 0.4 mm

3.Closed print chamber : Yes, fully enclosed

4.Connectivity : Ethernet, USB cable, Wi-Fi

Requirements

1.Software : 3DWOX

2.Operating system(s) : Windows

Group assignment 3D printer test:

We went to Thingiverse and downloaded a 3d test file as shown.

The link is:www.thingiverse.com

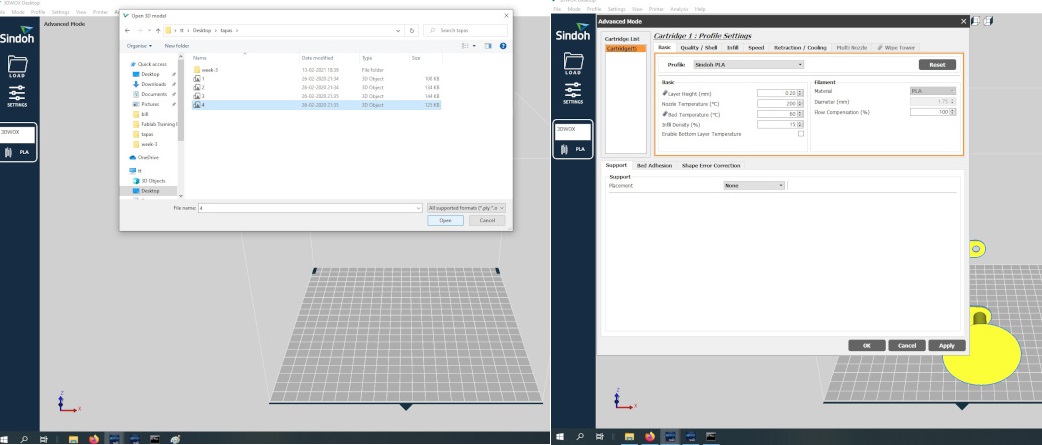

Then I loaded it in the 3DWOX software.

click here for more about group assignment

Design and 3D print an object that could not be made subtractively.

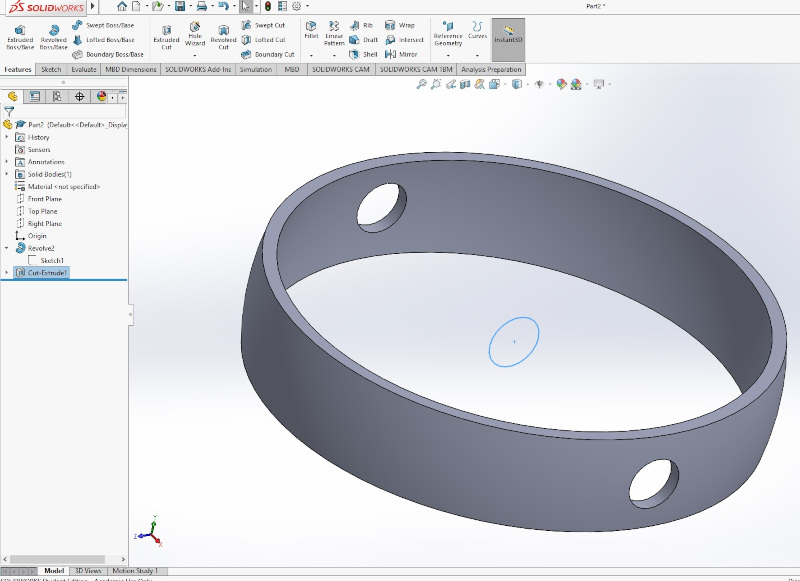

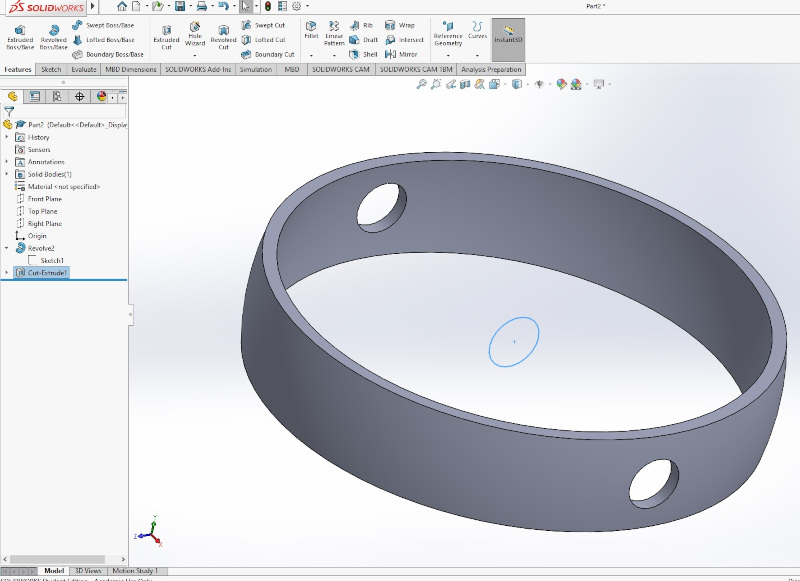

For my assignment i want to design gyroscope in solid works

There i need to create four parts for gyroscope

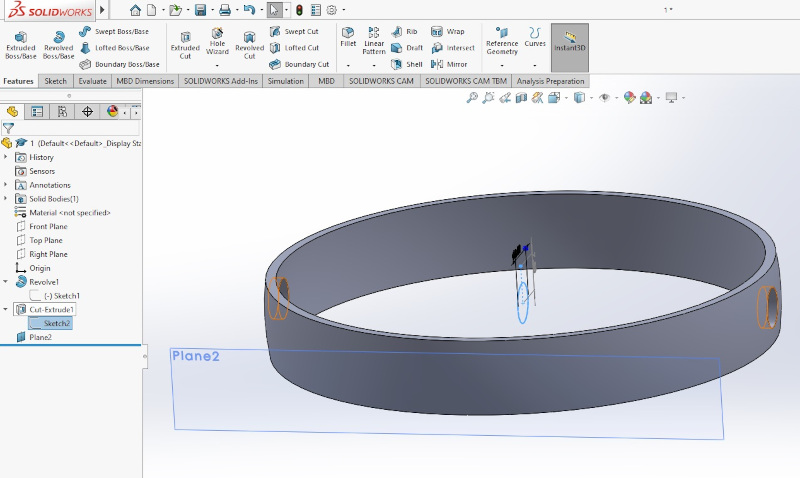

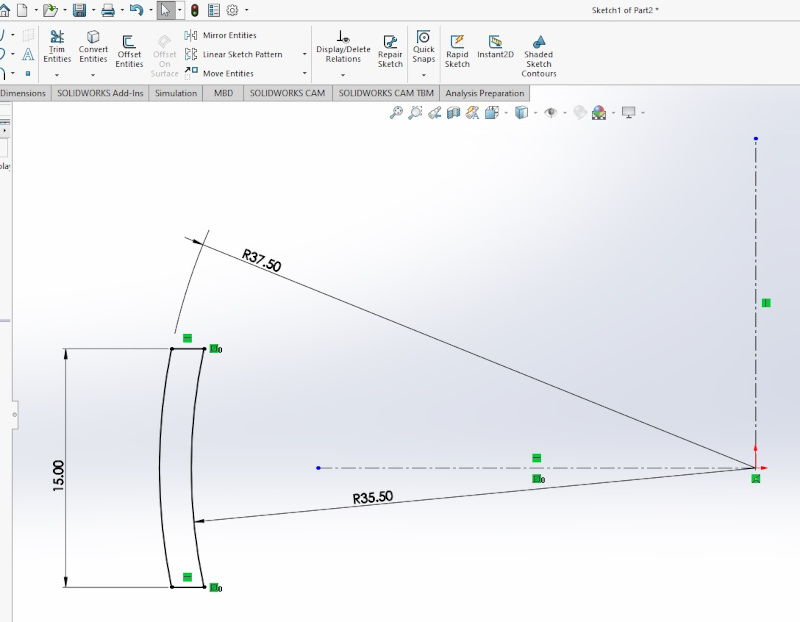

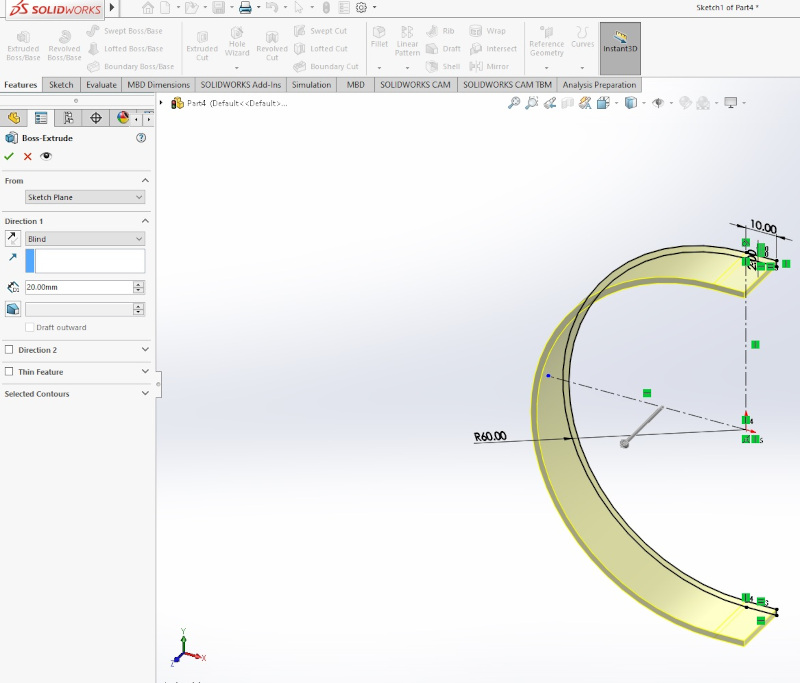

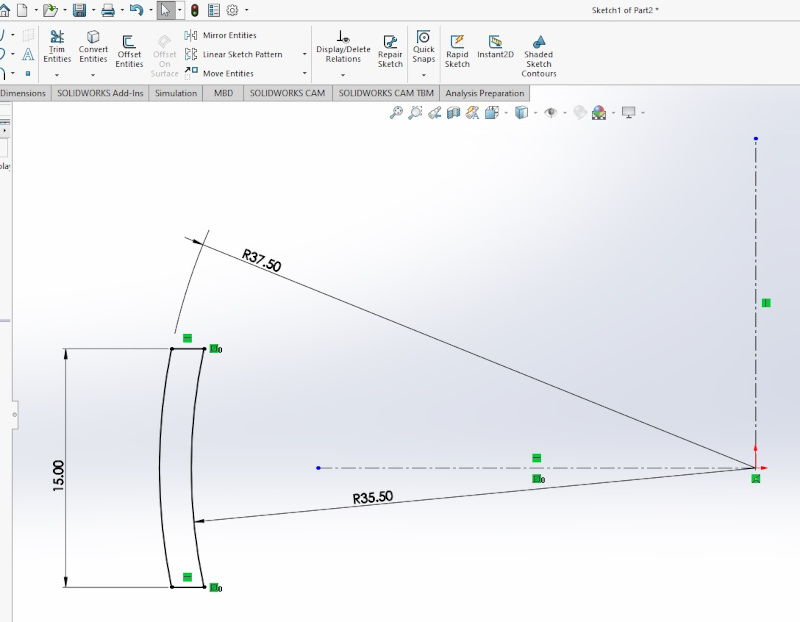

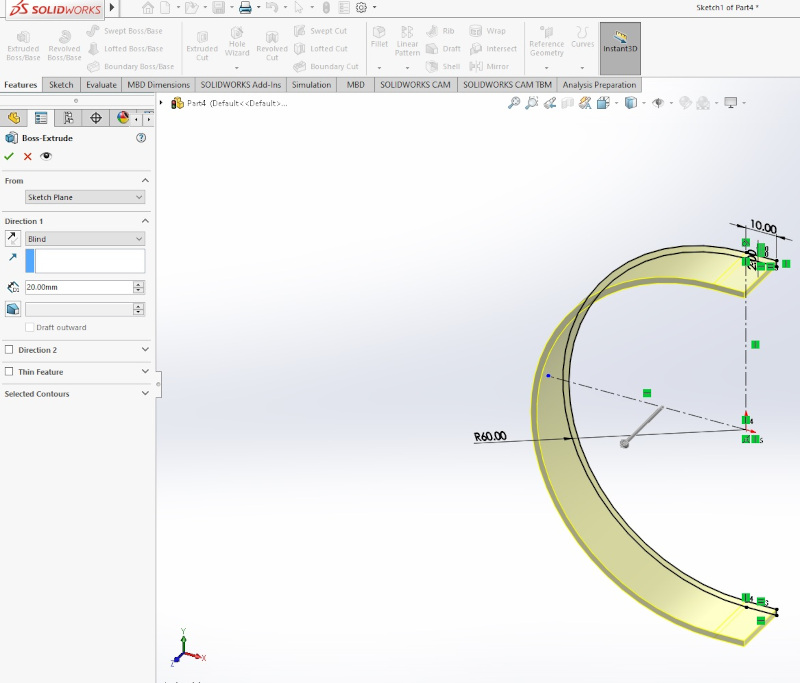

sketch the two arc from center line of x&Y asixes.

one arc is 50mm and other one is 48 mm

one arc is 50mm and other one is 48 mm

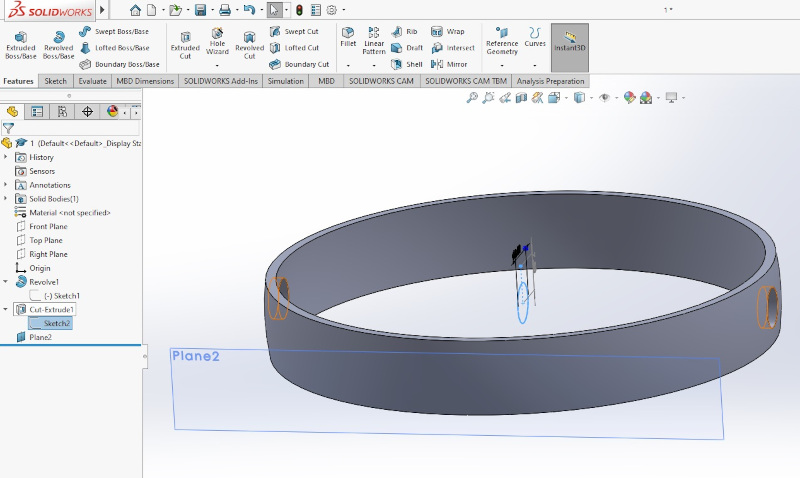

Then revolve using to using the radius

Height of the product 20mm

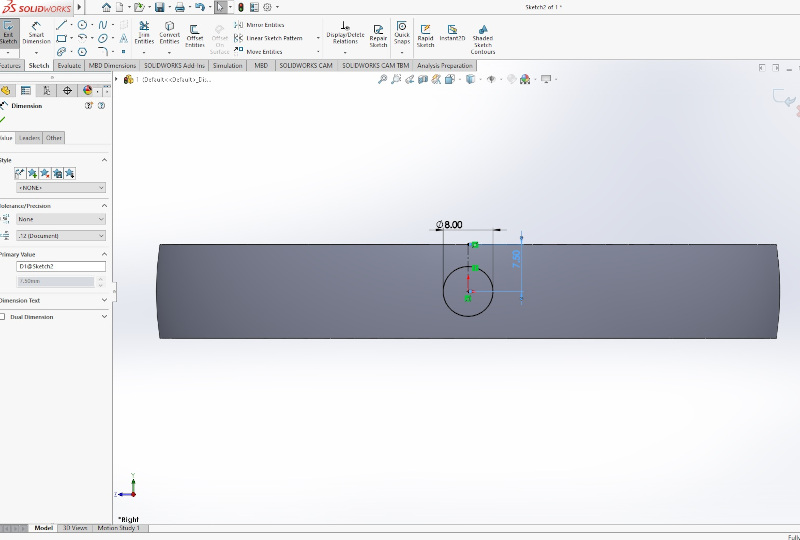

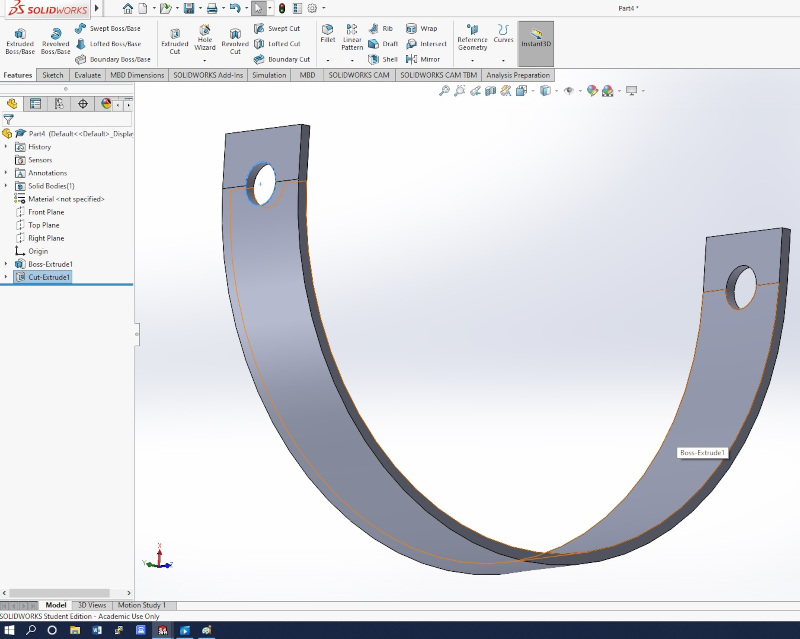

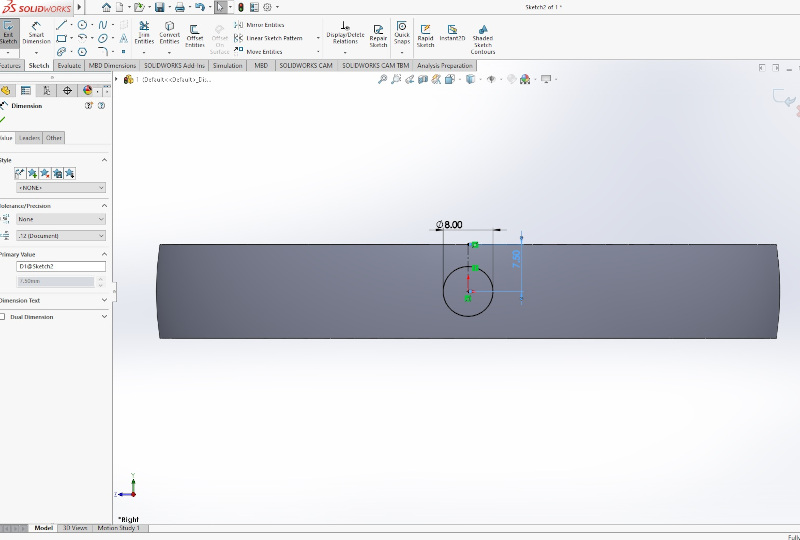

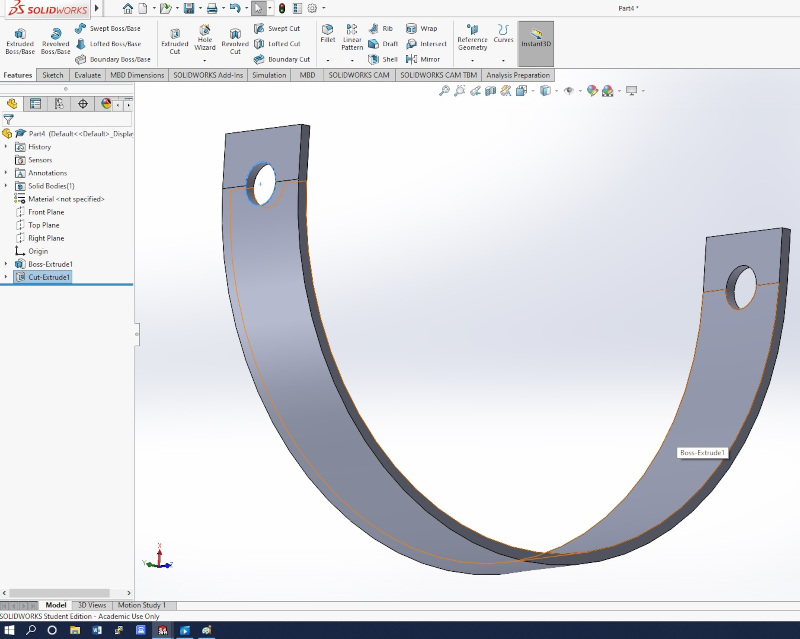

Select right plan and sketch a circle dia is 8 mm in the center and go to

extrude cut and make it all trough both.

select front plan and distance from center is 16 mm

sketch a circle of 8mm dia and select extruded boss up to surface,

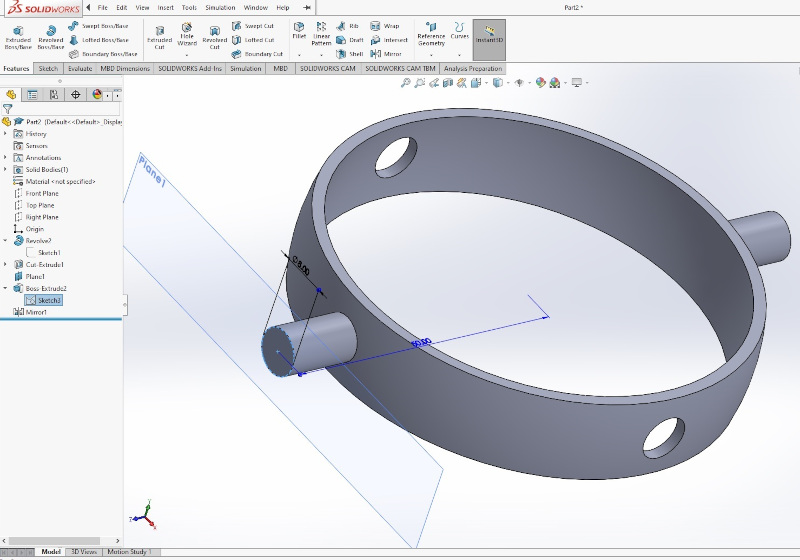

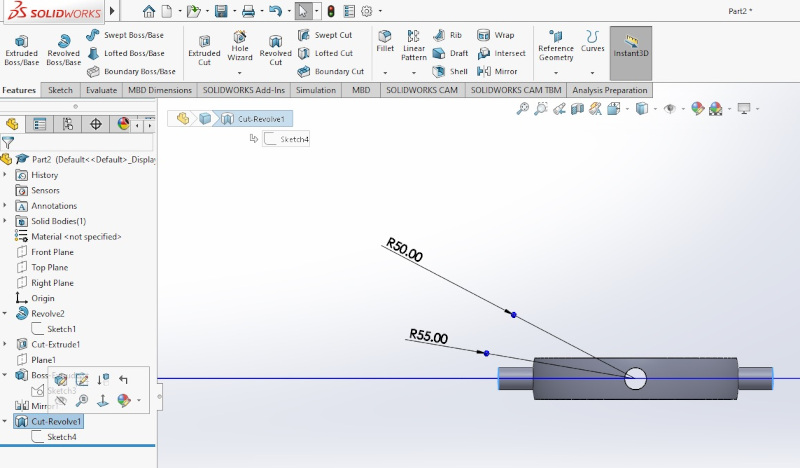

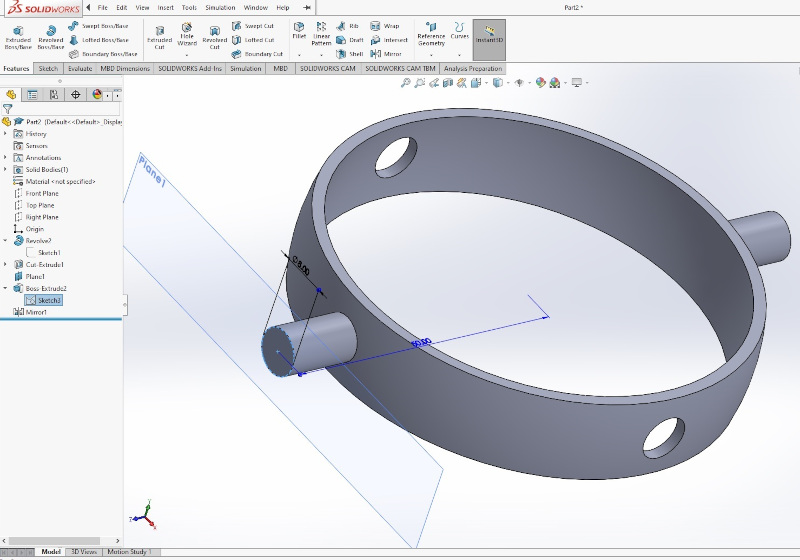

2nd part is similarly same,select front plan and distance from center is 16 mm

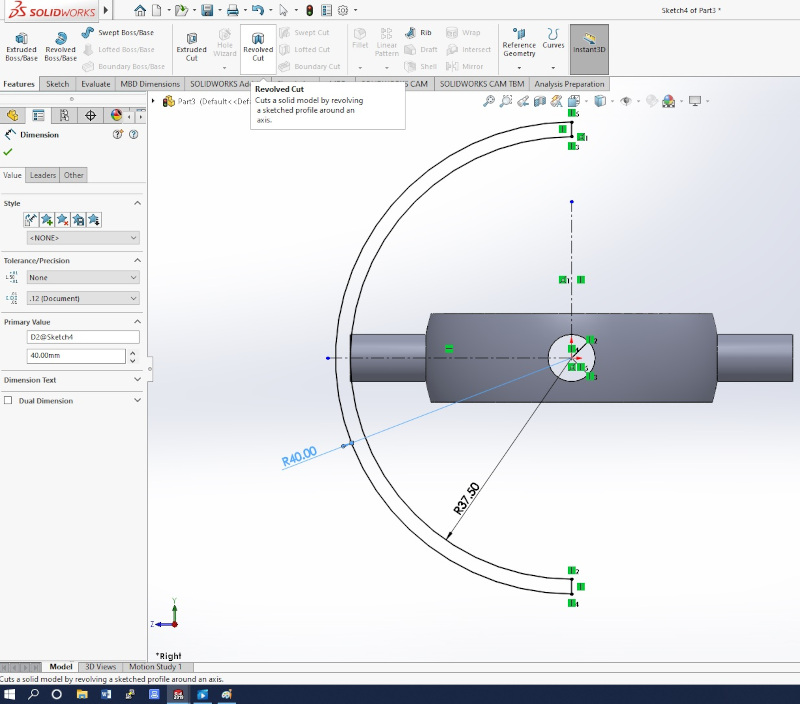

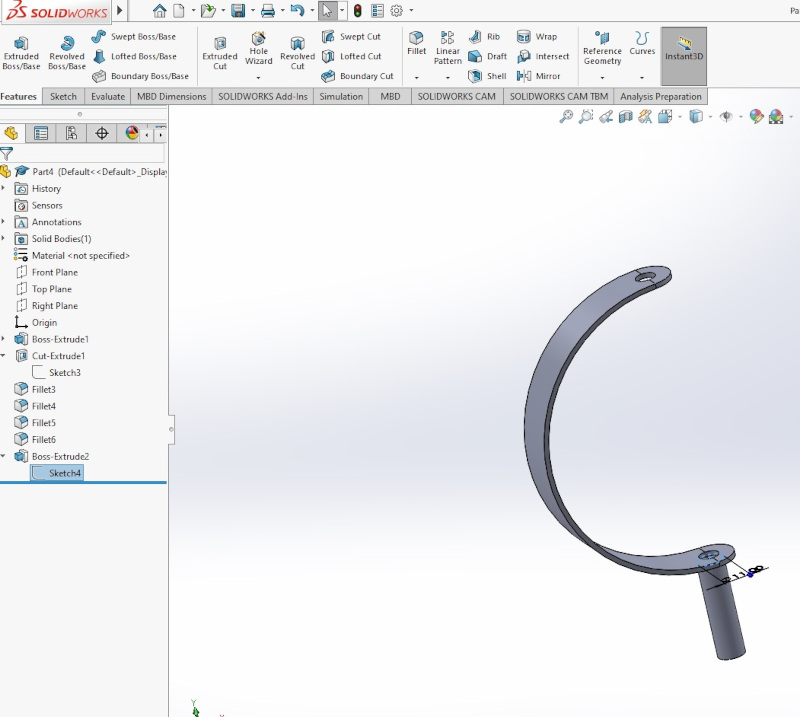

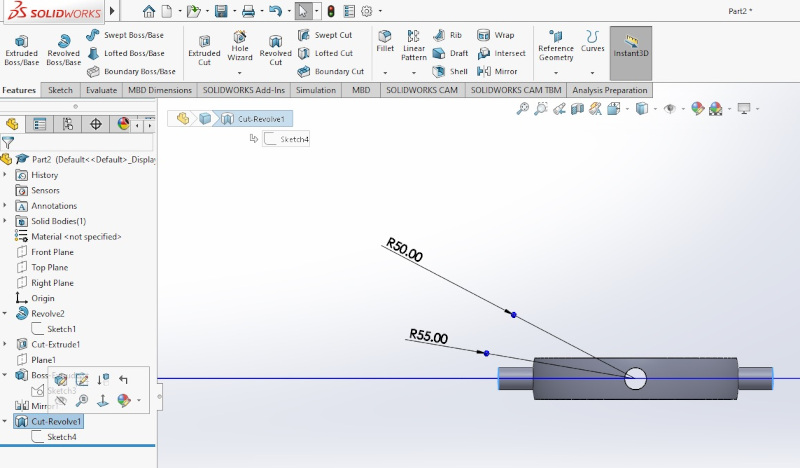

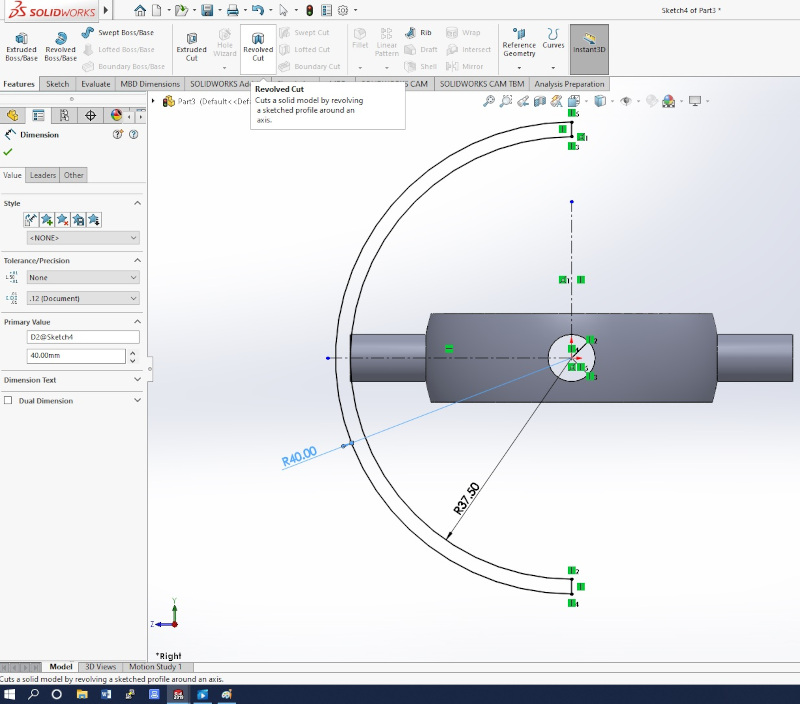

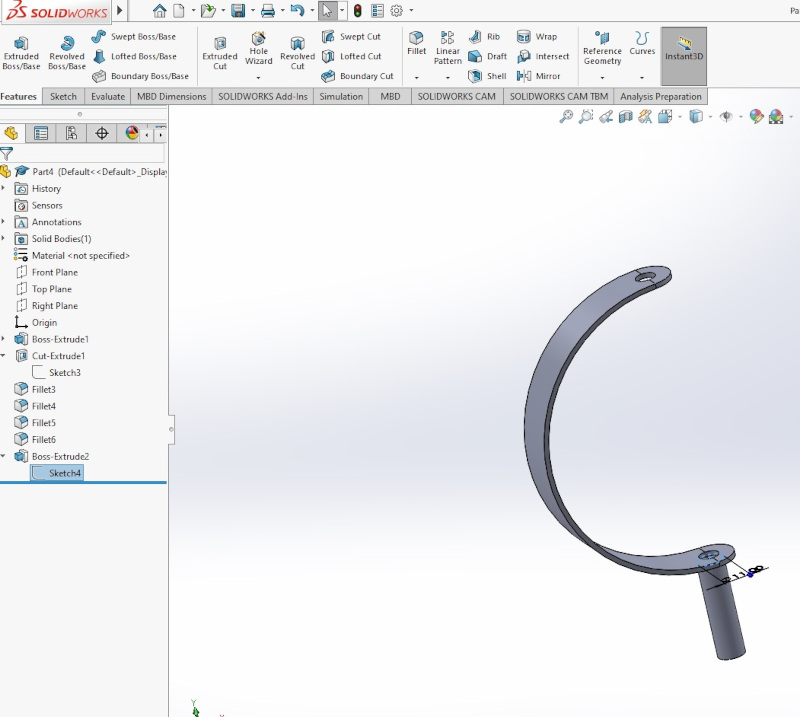

select front plan and draw reference line x&y, draw the two center arc one is 37.5mm and other one is 35.50mm

Right plan and sketch a circle dia is 8 mm in the center and extruded cut condition is through all side

select front plan and select it and other plan make distance up to surface. and make it mirror to upper side.

for assembling the edge shroud be proper circle,

create half circle th distance 50 and 55 mm from center do extruded cut in 360 degree.

Gyroscope base stand

Subtractive manufacturing process involves removing sections of a material by

machining or cutting it away. Creating a Sculpture from wood is Subtractive Process.Additive manufacturing process is a process that adds successive layers of material to create an object. Creating a terracotta sculpture by adding soil part by part is Additive Process.

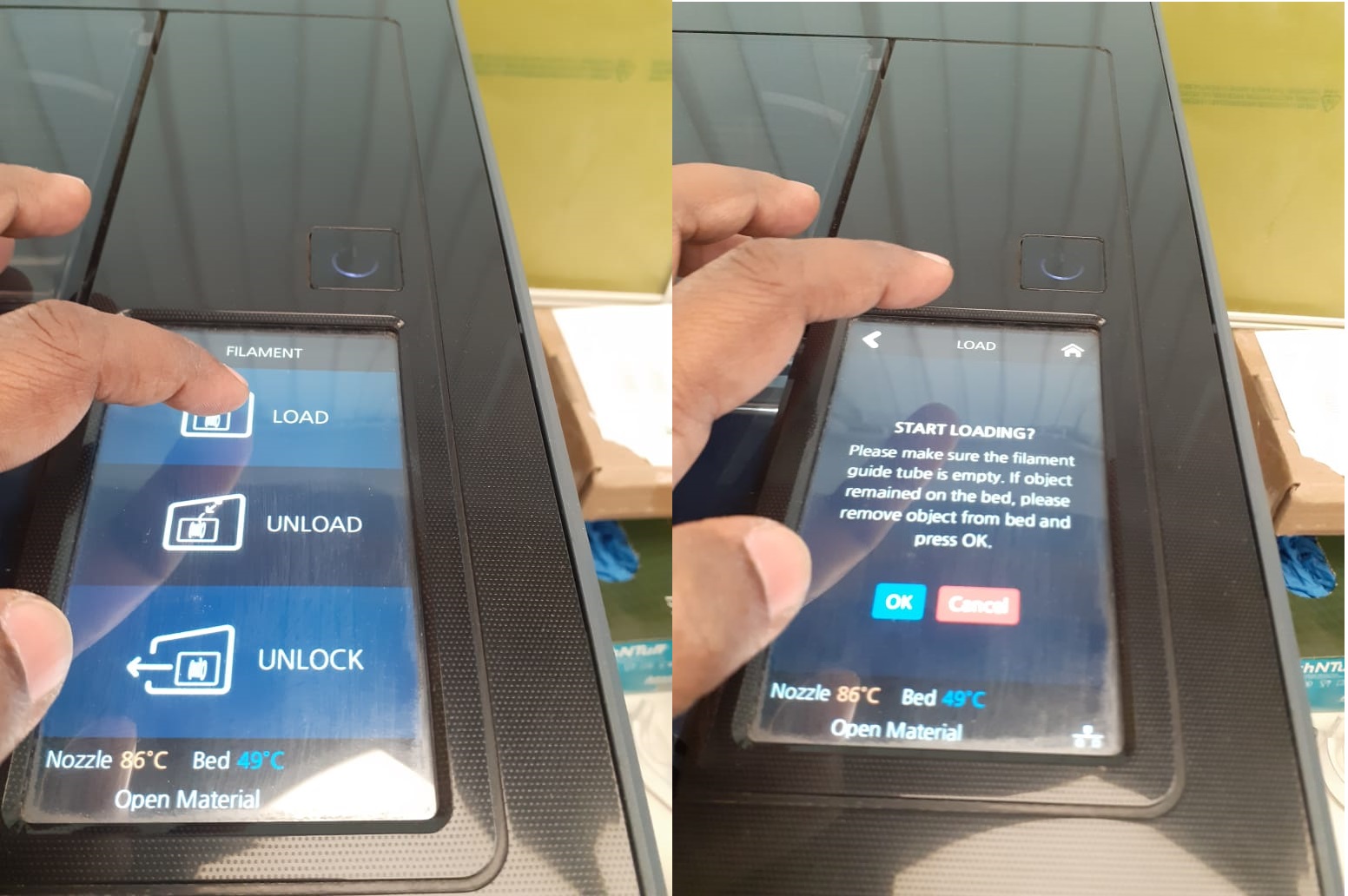

In my fab lab the sindoh printer caterige which was recived from fabfoudation was finsihed, we tried to bring some local PLA which put into the printer but printing job is not completing ,job is getting mesh in between. We contacted sibu he change the firmware and change to generic printing.

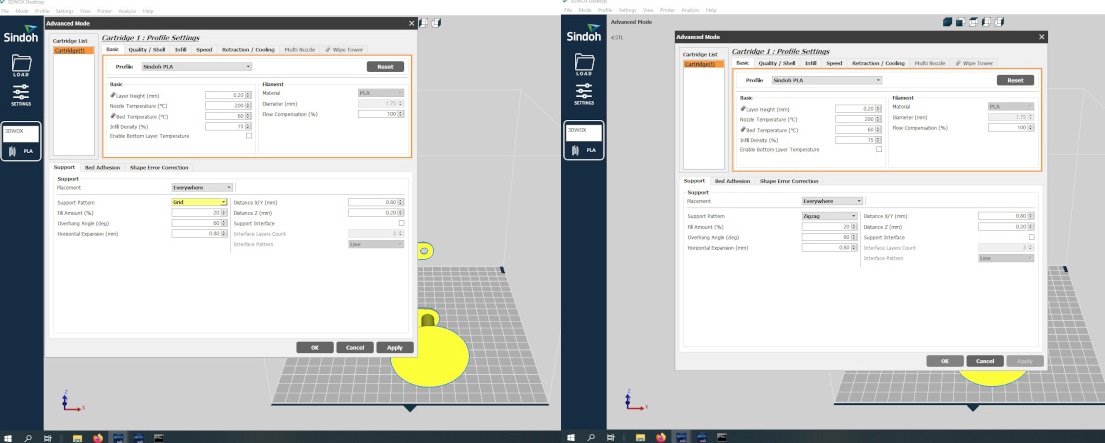

Further, the design was saved in .stl format and then uploaded in software of 3D printer which is 3DWOX in our case. After uploading the image, there are various option of increasing and decreasing the dimensions, orientation of print etc. I decreased the size of my design so that the printer may print it quickly and less material is used. Further I view the formation of base and the layers in my design and then calculated it for savin it in G-Code. G-Code is the language by which the printer understands the inputs and converts the inputs into a desired output. The images of my work in 3DWOX software is shown in the images below:-

After print the final product is gyroscope. I present this to My Director he is very happy and said me put in shelf in him chamber

Explanations about why the object is easily not made subtractively The idea was looking more complex at first but it needs to design

something that can only be manufactured using 3D printing. So coming to how a 3D printer works: A 3D printer

is like any CNC machine and it runs on G code, which is generated from a 3D model by software. In our case we used

Sindho and converting the 3D model into G code, which the machines understand. What happens is the that the software

sindho the 3d Model into a series of layers and then convert this data into a series of G code instructions that the

machine can follow. In 3D printing, we are not limited by the constrains posed in normal manufacturing techniques,

hence we can cheat architecture into impossible shapes. In my assignment i design Gyroscope which is composed essentially of

5 parts: gyroscope base ,support, outer gimbal , inner gimbal and rotor , so here i develop the base and support is a single one .

Each part is locked with another the reason you cannot make my model subtractively is because, it is one structure locked inside another one and the base is curve.

This would be very difficult to make using any regular milling or casting operation, but can be done with ease in a 3D printer.

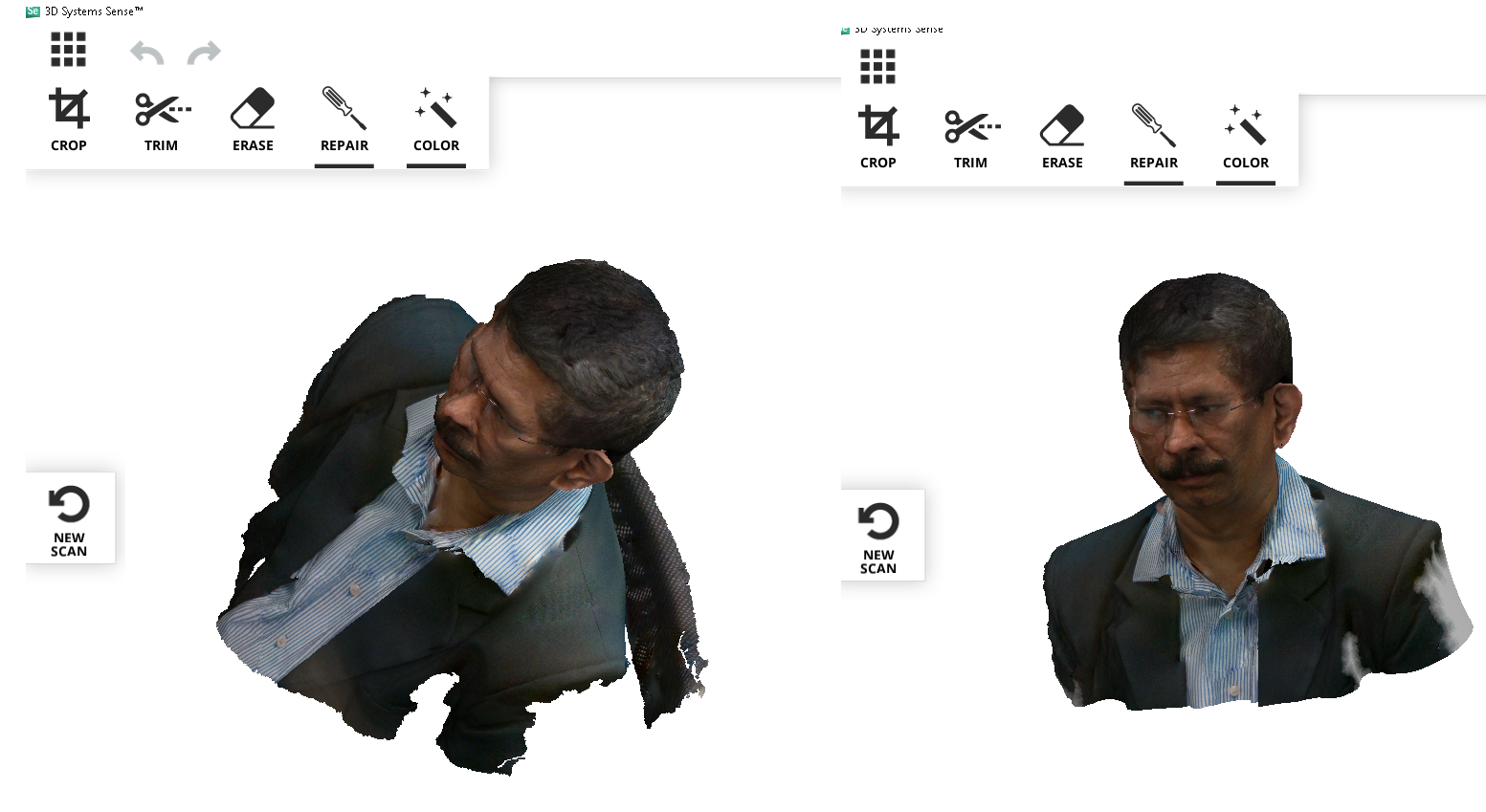

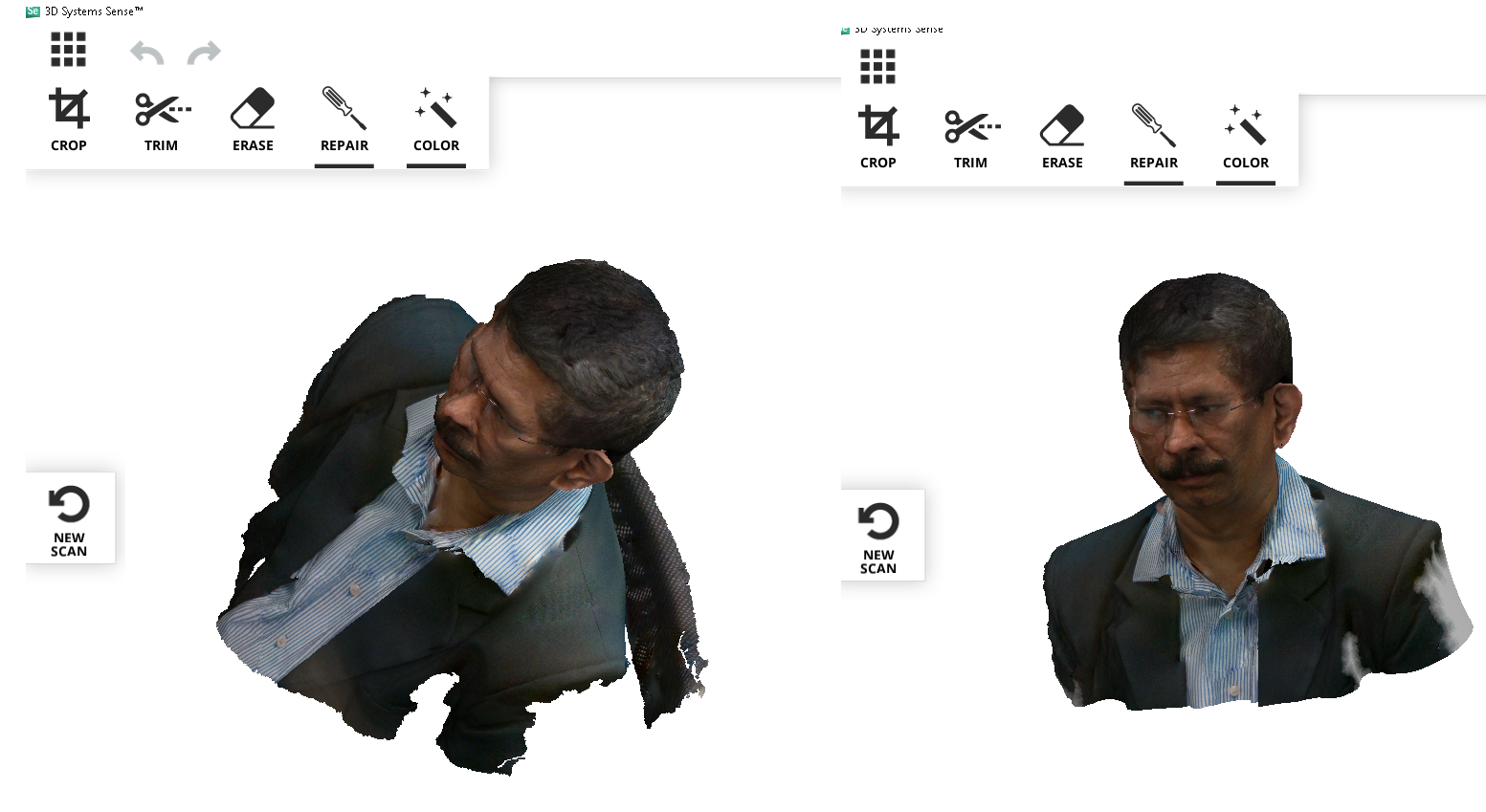

3D scanning :-In my fablab, sense 3d scanner from 3d system is available,Capture your world in 3D and discover the power of physical photography with the Sense 3D scanner. Savor every dimension of your favorite memories: Graduation day. Minimum scan volume: 0.2m x 0.2m x 0.2m. Maximum scan volume: 3m x 3m x 3m.I did this scanning one month back , one of official gust visited our fab lab that time i did 3d scan of his statue.

Trimming the unnecessary or crack scan and make it solidified.As the statue has to be submitted to him so i did print in sindho

3D Scanning using mobile:-

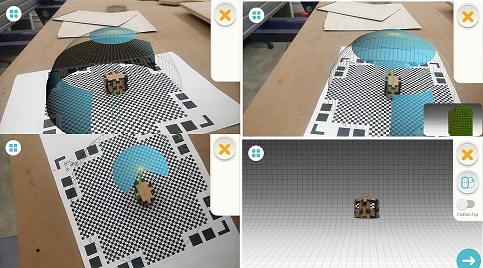

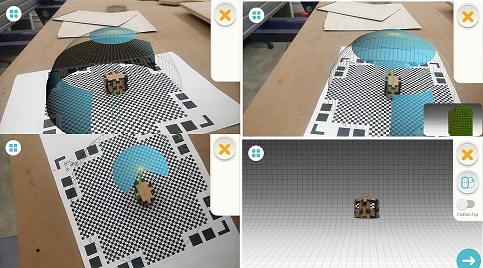

For 3D scanning, I have used a mobile

application called Qlone. The app is very user friendly and easy to use. The main requirement of the app is that it would scan the object placed only on AR Mat.

This mat is easily available along with the Qlone app and can be printed on a simple A-4 size paper. The image of the AR mat required for Qlone app is shown below:-

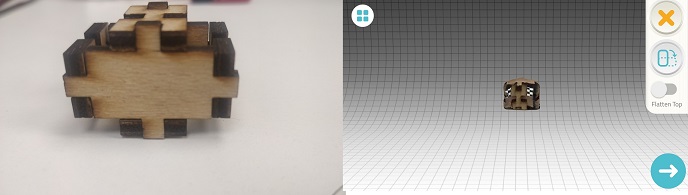

Further, I scanned the image of a pressfit kit sample. The original image of the Pressfit kit was as under:-

The scan result obtained was more or less good but not as good as expected. Hence, I didn't print the object and have just learnt about the process of 3D scanning. -

Click to download the files :

For 3D scanning, I have used a mobile application called Qlone. The app is very user friendly and easy to use. The main requirement of the app is that it would scan the object placed only on AR Mat.

This mat is easily available along with the Qlone app and can be printed on a simple A-4 size paper. The image of the AR mat required for Qlone app is shown below:-